Choosing between nylon braided hoses and stainless steel braided hoses depends on your specific needs. GONGGONG is a trusted manufacturer of braided hoses. When choosing hoses, people consider factors such as durability, pressure rating, temperature resistance, flexibility, weight, corrosion resistance, cost, and common applications. Some choose nylon braided hoses because of their flexibility, while others choose stainless steel braided hoses because of their high strength. Comparing the characteristics of these two types of hoses helps people choose the product that best suits their needs.

Key Takeaways

- Nylon braided hoses are lightweight and flexible, making them ideal for home use and small-scale operations. Stainless steel braided hoses are very strong and can withstand high pressure, making them suitable for high-intensity operations. Consider your project requirements and take into account the hose’s pressure resistance, temperature resistance, and flexibility. Nylon hoses are generally less expensive, while stainless steel hoses have a longer service life and are resistant to chemical corrosion. Always ensure that the hose is compatible with the fluid you are using to guarantee safe and reliable operation.

Nylon or Stainless Steel Braided Hose Overview

GONGGONG is a leading company in the braided hose industry. They produce a wide variety of hoses for different applications, including household, industrial, and bathroom hoses. GONGGONG is committed to producing safe and high-quality products.

What is a Nylon Braided Hose?

Nylon braided hoses typically have an inner layer made of PVC, making them strong and durable. The outer layer is wrapped with nylon fiber braids. This design makes the hose easy to bend and lightweight. Many people choose nylon braided hoses when they need to move or bend the hose frequently. Nylon braided hoses are less prone to tangling or overstretching, making them ideal for use in confined spaces. GONGGONG conducts rigorous quality testing on every nylon braided hose to ensure its safety and durability.

What is a Stainless Steel Braided Hose?

Stainless steel braided hoses have an inner tube made of nylon or PVC. The outer layer is wrapped with stainless steel wire, making stainless steel braided hoses very strong, durable, and safe. Compared to nylon braided hoses, stainless steel braided hoses can withstand higher pressure and temperatures. Many companies use stainless steel hoses in heavy-duty applications. GONGGONG sells stainless steel braided hoses for both hot and cold water. These hoses will not rust and have a lifespan of several years.

Tip: You can choose between nylon braided hoses or stainless steel braided hoses according to your needs. Nylon braided hoses are easy to bend and install. Stainless steel braided hoses are robust and durable, offering a longer service life in harsh environments.

Main Differences at a Glance

| Feature | Nylon Braided Hose | Stainless Steel Braided Hose |

|---|---|---|

| Outer Braid Material | Nylon | Stainless Steel |

| Inner Tube Material | PVC | Nylon or PVC |

| Flexibility | High | Moderate |

| Pressure Resistance | Moderate | High |

| Corrosion Resistance | Good | Excellent |

| Typical Uses | Home, light industry | Heavy-duty, industrial, sanitary |

You should choose either nylon or stainless steel based on your needs. Each material is suitable for different applications.

Braided hose Durability and Longevity

Nylon Braided Hose Durability

Nylon braided hoses are robust and durable, suitable for many everyday applications. The outer layer is made of tough nylon fibers, protecting the inner tube from damage. This hose is resistant to abrasion. Many people like nylon braided hoses because they are easy to bend and do not easily crack. This robust nylon braided hose is suitable for household plumbing and light factory operations.

GONGGONG conducts quality inspections on every nylon braided hose to ensure its superior quality. This hose can be bent and twisted without deforming. Due to its high strength, it can be used for a long time, even in busy environments. Nylon braided hoses are commonly chosen when a flexible and durable hose is required.

Note: Nylon braided hoses are ideal for locations where objects move frequently. Their strength helps prevent leaks and breakage.

Stainless Steel Braided Hose Strength

Stainless steel braided hoses are known for their high strength and long lifespan. Their outer layer is made of stainless steel wire, effectively protecting the hose from cuts and impacts. This makes stainless steel braided hoses extremely tough and durable. Many factories and large construction projects use stainless steel braided hoses because they perform exceptionally well in high-pressure and high-intensity working environments.

Stainless steel braided hoses are ideal for high-intensity operations. They do not rust and can withstand water or high-temperature environments. GONGGONG’s stainless steel braided hoses undergo rigorous strength testing. People trust this hose for critical operations requiring robustness, durability, and reliable safety.

- Stainless steel braided hoses offer the following advantages:

- Maintain high strength even in harsh environments

- Good pressure and heat resistance

- Long service life with virtually no maintenance

Choosing between nylon and stainless steel braided hoses depends on your required strength. Both types of hoses work well, but each is best suited for different applications.

Braided hose Pressure and Temperature Resistance

Pressure Ratings: Nylon vs Stainless Steel

Pressure is a crucial factor when choosing hoses. Some people require hoses capable of withstanding high pressure. Nylon braided hoses are suitable for home and small jobs. They can withstand some pressure, but not ultra-high pressure. These hoses are not designed for high-pressure environments. For example, the RHP 230 series hoses have a nylon outer layer and are not suitable for high-pressure hydraulic systems or power steering lines.

Stainless steel braided hoses are better suited for high-pressure environments. They can withstand much higher pressures than nylon hoses. The HPS 351 series PTFE flexible hoses have a stainless steel outer layer and can withstand pressures up to 1750 PSI. This makes stainless steel braided hoses ideal for large buildings and factories. People choose stainless steel braided hoses when they need a robust, durable, and reliable hose.

Tip: Always check the pressure rating before using a hose. Stainless steel braided hoses perform excellently even under high pressure.

Braided hose Temperature Range Comparison

Temperature resistance is also an important factor to consider. Nylon braided hoses can withstand the temperatures required for most home and small jobs. These hoses work well at normal temperatures but are not suitable for extremely high temperatures.

Stainless steel braided hoses are ideal for high-temperature environments and can be used for extended periods even at high temperatures. A single hose can withstand temperatures up to 550 degrees Fahrenheit (approximately 288 degrees Celsius). This means the hose won’t be damaged even at high temperatures.

“This product won’t deteriorate over time. Its lifespan should be as long as your car. The hose can withstand temperatures up to 550 degrees Fahrenheit (approximately 288 degrees Celsius). This is a very high temperature for a hose, except for all stainless steel welded hoses. It’s a fantastic product.”

People who need hoses for use in high-temperature environments will choose stainless steel braided hoses. It’s safe, reliable, and performs excellently in high-temperature conditions.

Braided hose Flexibility and Installation

Braided Nylon Hose Flexibility

Nylon braided hoses are very flexible and suitable for a variety of environments. They can be easily installed even in confined spaces. Many people choose nylon braided hoses because of their ease of bending. This type of hose can easily navigate around corners and behind obstacles. You don’t need special tools to move or adjust its shape. The hose is not prone to tangling, so the water flow won’t be interrupted.

- Nylon braided hoses are easy to bend, so you can place them in tight spaces.

- They don’t tangle easily, so you can move them easily.

The minimum bending radius of nylon braided hose is 5 inches (approximately 12.7 cm). This means you can bend it quite a bit without damaging it. GONGGONG’s nylon braided hose is very time-saving to install. It’s suitable for a variety of layouts. Using this flexible hose, people can get their work done faster.

Stainless Braided Hose Bend Radius

While stainless steel braided hose is strong, it’s not as flexible as nylon braided hose. It feels stiffer and has a smaller bending radius. When using stainless steel braided hose, you must plan your path in advance. The hose requires more turning space. Sometimes, you need to use special tools to bend it properly.

- Stainless steel hoses are stiffer and not easy to bend.

- This makes them difficult to install in tight spaces.

- You may need tools and careful planning to bend them without damage.

There is no fixed minimum bending radius for stainless steel braided hose. However, if bent excessively, the hose may break or damage the ends. If you need a flexible hose, nylon braided hose is a better choice. If you need a strong and durable hose, stainless steel braided hose is ideal.

| Hose Type | Minimum Bend Radius |

|---|---|

| Nylon Braided Hose | 5 inches |

| Stainless Steel Braided Hose | N/A |

Flexible hoses help you install faster and easier. Choose nylon braided hose or stainless steel braided hose based on your space and needs.

Braided hose Weight and Handling

Lightweight Benefits of Nylon

Nylon braided hose is known for its lightweight nature. This makes it easy to handle and install. Workers can easily move nylon braided hose. This type of hose is ideal for applications where weight is a concern, such as automobiles or small machinery. Nylon braided hose is often chosen for jobs requiring quick changes or frequent relocation.

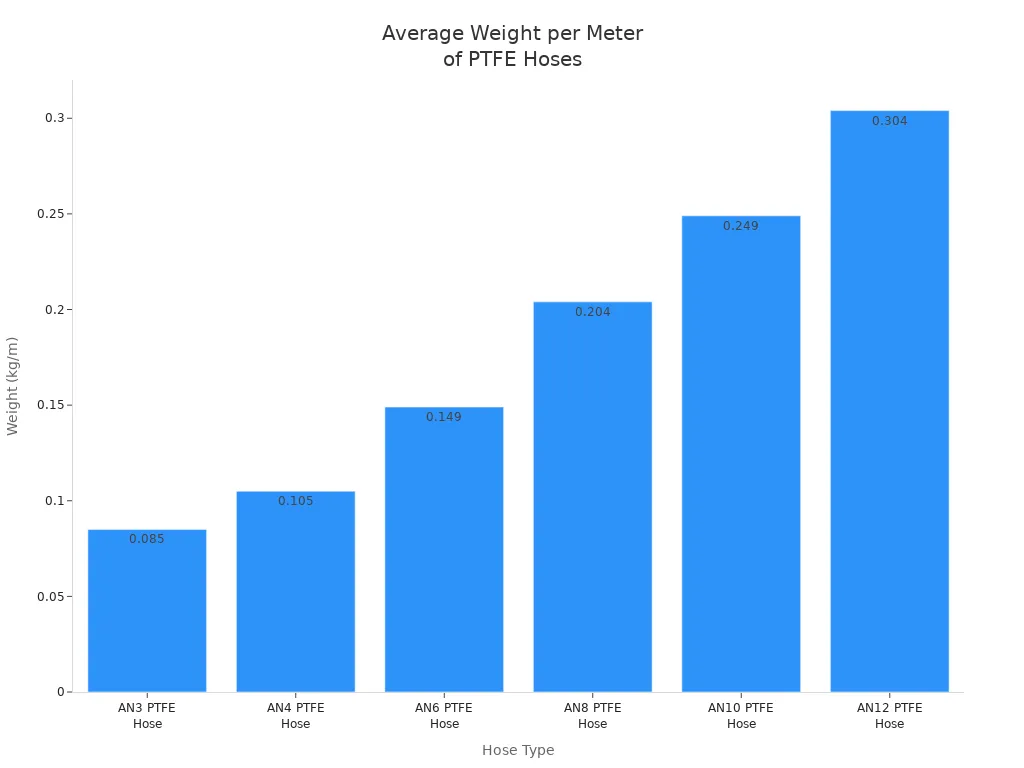

The advantages of nylon braided hose are obvious from the data. Nylon braided hose weighs approximately 0.057 kg per meter, which is much lighter than many other types of hose. The table below compares the weight of different hoses:

| Hose Type | Weight (kg/m) |

|---|---|

| Lightweight Nylon Braided Hose | 0.057 |

| AN3 PTFE Hose | 0.085 |

| AN4 PTFE Hose | 0.105 |

| AN6 PTFE Hose | 0.149 |

| AN8 PTFE Hose | 0.204 |

| AN10 PTFE Hose | 0.249 |

| AN12 PTFE Hose | 0.304 |

The following diagram shows a comparison of nylon braided hoses with other hoses:

Tip: Lighter hoses help reduce strain during installation and are easier for everyone to handle.

Handling Stainless Steel Braided Hose

Stainless steel braided hoses are strong but also heavy. Workers will notice the weight difference when handling or moving these hoses. The extra weight means that the stainless steel braided hose remains stable after installation. This is especially important in environments requiring stability.

Stainless steel braided hoses are frequently used in factories and large buildings. The hose’s weight makes it feel stable. It can resist movement caused by water pressure or vibration. Handling stainless steel braided hoses may require more care, especially in confined spaces or when working at heights. Workers sometimes use tools to guide and position the hose.

Note: Heavier hoses (such as stainless steel braided hoses) are more durable but may require more effort during installation.

Braided hose Corrosion and Chemical Resistance

Nylon Hose Chemical Compatibility

Nylon braided hoses can handle a variety of chemicals commonly found in everyday life. They can be used with water, oil, and some cleaning agents. People choose nylon braided hoses when they need a lightweight and flexible hose. However, nylon is not resistant to all chemicals. Strong acids and alkalis can corrode nylon hoses, causing leaks or ruptures.

The table below shows the reaction of nylon braided hoses to different chemicals:

| Chemical Type | Resistance Status |

|---|---|

| Strong Acids | Not Resistant |

| Strong Bases | Not Resistant |

| Many Other Chemicals | Good Resistance |

Nylon braided hoses are best suited for low-pressure operations. Not recommended for corrosive chemicals. These hoses are suitable for household and light factory operations. They offer good flexibility and some chemical resistance.

Tip: Always confirm the type of liquid you will be using before selecting a nylon braided hose. This helps prevent damage and ensures safety.

Stainless Steel Hose Corrosion Resistance

Stainless steel braided hoses offer excellent rust and chemical resistance. Their outer layer is protected by 304L stainless steel, making them suitable for high-intensity operations and harsh environments. Stainless steel hoses are suitable for factories, chemical plants, and high-temperature environments.

- Stainless steel braided hoses will not rust from water or steam.

- In harsh environments, they have a longer service life than nylon braided hoses.

- Stainless steel hoses can withstand a wide range of temperatures and chemicals.

Many people choose stainless steel braided hoses because of their strong resistance to chemical corrosion and long service life. They function well even in high-viscosity fluids and high-pressure environments.

Note: Stainless steel braided hoses are the best choice for factories and chemical operations. They are safe and reliable, and can be used for a long time even in harsh environments.

Braided hose Cost Comparison

Nylon vs Stainless Steel Hose Pricing

Price is an important consideration when choosing hoses. Nylon braided hoses are less expensive than stainless steel braided hoses. Many people buy nylon hoses for home work and small businesses. Nylon hoses are cheaper, thus saving money. They still perform well in many applications.

Stainless steel braided hoses are more expensive. They use higher-quality materials and special manufacturing processes. These hoses are stronger and more durable, and can be used for a longer time even in harsh environments. Factories and large construction projects often choose stainless steel hoses. They require safe and durable hoses.

Below is a price list for two types of hoses:

| Hose Type | Average Price (per meter) |

|---|---|

| Nylon Braided Hose | $3 – $7 |

| Stainless Steel Braided Hose | $8 – $15 |

Note: Prices may vary if you choose a larger size hose or require special features.

Value for Money

People want to know if they’re getting value for their money. Nylon braided hoses are cost-effective for jobs that don’t require high pressure or high temperatures. These hoses are suitable for home use and small machinery, and are easy to bend and move. Using nylon hoses can save costs and speed up operations.

Stainless steel braided hoses, on the other hand, are good value for money for high-intensity jobs. They can withstand high pressure, high temperatures, and strong chemical corrosion. Many companies consider stainless steel hoses a wise choice, as they help ensure safety and reduce maintenance.

When choosing a hose, people should consider the intended use, budget, and hose lifespan. Choosing the right hose can save money and ensure everything runs smoothly.

Braided hose Applications and Suitability

Automotive and Industrial Uses

Many people use braided hoses in cars and factories. These hoses are used to transport substances such as oil, fuel, and coolant. Engines and braking systems are often subjected to high pressure. Nylon braided hoses are suitable for small car operations. They are easy to bend and install. Stainless steel braided hoses perform better in high-pressure and high-temperature environments, making them ideal for racing cars and large trucks. Factories also use these hoses to transport chemicals and for hydraulic systems. Workers choose stainless steel braided hoses for high-intensity jobs. These hoses will not be damaged by vibration or high temperatures. GONGGONG offers hoses in various sizes and lengths to help everyone find the right hose for their job.

Tip: Before choosing a hose for your vehicle, be sure to confirm the required pressure and temperature.

| Application Type | Best Hose Type | Key Feature |

|---|---|---|

| Light automotive | Nylon braided hose | Flexibility |

| Racing applications | Stainless steel braided hose | High pressure resistance |

| Industrial machinery | Stainless steel braided hose | High temperature and pressure |

Sanitary and Food-Grade Uses

Hose used in food and cleanroom operations must be safe and reliable. Braided hoses are used in kitchens, restaurants, and food factories to transport water and food. Stainless steel braided hoses are ideal as they are rust-resistant and maintain water quality. Nylon braided hoses are suitable for situations requiring bending. GONGGONG hoses are manufactured in strict accordance with safety regulations.

Food-grade and clean-grade hoses must pass multiple tests, including:

- US Food and Drug Administration (FDA) regulations for hoses that come into contact with food

- EU Food Safety Regulation 1935/2004

- NSF/ANSI 51 Standard for Safe and Easy-to-Clean Hose

GONGGONG hoses have passed these tests and are therefore safe for use in kitchens and beverage dispensers. Special sizes are available to meet individual needs. High-pressure food processing plants use stainless steel braided hoses, which ensure the safety of food and water under varying pressure and temperature conditions.

Note: Always use certified food-grade or drinking water hoses.

Choosing the Right Braided hose

Decision Factors

Choosing the best braided hose depends on several factors. You should consider the nature of your work and where the hose will be used. Understanding the type of fluid the hose will be delivering is also important. The table below compares nylon braided hoses and stainless steel braided hoses for high-pressure work:

| Feature | Nylon Braided Hose | Stainless Braided Hose |

|---|---|---|

| Durability & Abrasion Resistance | Good; works for most jobs | Excellent; best for tough places |

| Weight | Light; great for fast cars | Heavy; matters if weight is important |

| Flexibility | Very flexible; easy to put in | Not very flexible; hard to bend |

| Pressure Rating | Very good; fine for many systems | Excellent; best for high pressure |

| Cost | Usually cheaper | Costs more |

| Installation Risk | Not likely to scratch things | Can scratch surfaces |

You should also consider where the hose will be used. Here are some things to keep in mind:

- If the hose will rub against rough objects or move frequently, it needs to be strong enough. Steel wire or high-strength fibers help solve this problem.

- If the hose is UV resistant, its lifespan in sunlight will be longer. PVC or special fibers can prevent sun damage.

- Hose used for outdoor work needs to be able to withstand various weather conditions. Steel wire and high-strength fibers ensure that the hose works properly in rain or sunlight.

Users of nylon hoses report that they are lightweight, flexible, and easy to assemble. Stainless steel hoses are robust and durable, capable of withstanding higher pressures. However, some point out that stainless steel hoses are prone to overheating, potentially causing problems near the engine. Nylon hoses are better suited for nitrogen systems because they are flexible and less prone to vaporization. Stainless steel hoses are bulkier and may be difficult to install in confined spaces.

Tip: Always choose a hose that suits your operational needs. Consider your required pressure, heat resistance, and flexibility.

Choosing between nylon braided hoses and stainless steel braided hoses depends on your job requirements. Nylon hoses are strong, lightweight, and flexible, and are also less expensive than stainless steel hoses.

Advantages:

- Strong and lightweight

- Great at stopping scrapes and taking pressure

- Cheaper than stainless steel hoses

- Can be used in many jobs and bends easily

Disadvantages:

- Might not handle very tough weather

- Not as good against rust as stainless steel

Stainless steel braided hoses are better suited for high-pressure environments and have a longer lifespan. They are very strong and flexible. These hoses can withstand pressures up to 3,000 psi. They last 34% longer than hoses without additional support.

GONGGONG manufactures high-quality braided hoses suitable for a wide range of jobs. Before purchasing, always check that the hose can withstand pressure, high temperatures, and chemical corrosion.

FAQ

What are the main differences between nylon braided hoses and stainless steel braided hoses?

Nylon braided hoses are lighter and more flexible. Stainless steel braided hoses are stronger and can withstand higher temperatures and pressures. Each type of hose is suitable for different applications.

Can both types of hoses deliver hot water?

Both nylon braided hoses and stainless steel braided hoses can deliver hot water. Stainless steel braided hoses perform better in high-temperature environments. Nylon braided hoses are sufficient for most household hot water needs.

Are GONGGONG braided hoses safe for drinking water?

GONGGONG braided hoses adhere to stringent safety standards. They have passed drinking water safety and clean use tests. They are safe to use in kitchens and bathrooms.

Which hose is easier to install in confined spaces?

Nylon braided hoses are flexible and suitable for confined spaces. Stainless steel braided hoses are more rigid and require more installation space.

How long is the lifespan of GONGGONG braided hoses?

If used properly, GONGGONG braided hoses can last for many years. The company uses high-quality materials and strictly controls quality to ensure the hoses are safe, reliable, and perform excellently.