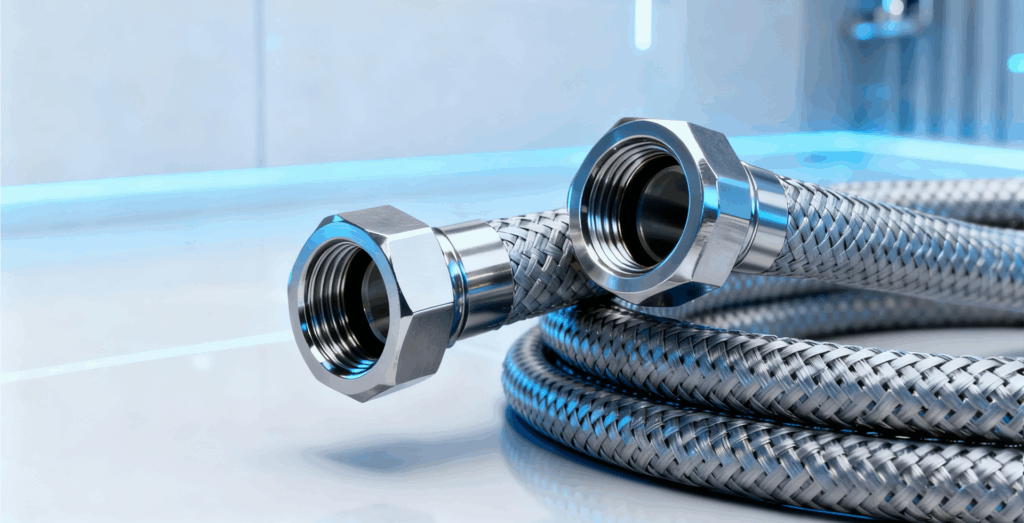

Many people encounter problems when using braided hoses. These problems include loose connections, aging materials, corrosion, overtightening, and damage. These can all lead to leaks, causing homeowners considerable worry. High-quality materials help prevent leaks. Most hose problems are easy to fix and repair. Hose products from reputable brands like GONGGONG can prevent leaks before they occur.

Key Takeaways

- Braided hoses can leak if the connections are loose, the materials are aging, or there is damage. Regularly checking the hose can prevent problems before they occur.

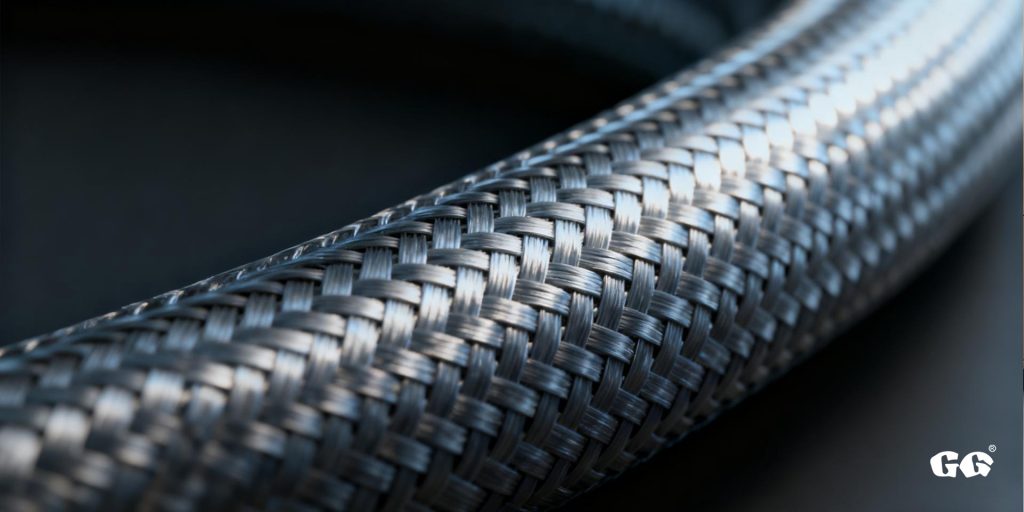

- Choose a strong, durable hose made of high-quality materials such as stainless steel. A strong hose lasts longer and leaks less.

- Proper hose installation is crucial. Always follow the manufacturer’s instructions. This helps ensure the hose’s safety and security.

- Inspect the hose every six months for cracks or bulges. Early detection can prevent bigger problems later.

- If you discover a leak, repair it immediately. Turn off the water and clean up any spilled water immediately. This will ensure your home stays safe and dry.

Causes of Leakage in Braided Hoses

Braided Hoses Material Aging and Wear

Braided hoses weaken over time. The flexibility of the hose’s inner wall gradually decreases, and cracks may appear. These cracks increase the likelihood of leaks. Leaks in hydraulic hoses also increase with age. The lifespan of textile braided hoses is approximately five to ten years. Stainless steel braided hoses can last ten to twenty years or even longer. Choosing hoses made from high-quality materials, such as those used by GONGGONG, helps extend their lifespan and maintain their strength.

Braided Hoses Loose Connections and Fittings

Loose joints in braided hoses often lead to leaks. Plumbers frequently encounter this problem. Connections can loosen due to wear, improper installation, or aging. If the joints are not tight, water will leak. Regularly checking the hose and ensuring proper installation helps prevent leaks. GONGGONG hoses use special joints to help maintain a tight connection.

Braided Hoses Over-Tightening and Seal Damage

Overtightening the fitting can damage seals and the inside of the hose. Excessive force can flatten the hose, creating weak points and obstructing water flow. Thinning of the hose walls leads to increased pressure, potentially causing the hose to burst. To avoid this, installers should:

- Tighten by hand first, aligning all parts.

- Use a torque wrench and tighten according to the manufacturer’s instructions.

- Do not overtighten or undertighten.

- Always follow the torque rule to ensure a leak-free hose connection.

This will protect the hose and maintain a strong seal.

Braided Hoses Corrosion and Environmental Factors

Corrosion reduces the strength of braided hoses and can cause leaks. Humid air and humidity can cause metal parts to rust. Extremely hot or cold weather exacerbates corrosion. Chemicals such as acids or salts can damage hose materials. Stainless steel braided hoses are more corrosion-resistant than hoses made of other materials, but they can still rust. GONGGONG uses high-strength stainless steel to prevent corrosion.

| Type of Corrosion | Description | Impact on Structural Integrity and Leakage Prevention |

|---|---|---|

| Uniform Corrosion | The metal wears evenly, thinning out. | Can lead to failure, but is easily observed. |

| Pitting Corrosion | Small holes form and rust attacks one spot. | Can make hoses weak and cause sudden leaks or bursts. |

| Stress Corrosion Cracking | Cracks show up when the hose is stressed in a rusty place. | Can break the hose quickly, sometimes without warning. |

Braided Hoses Excessive Pressure or Temperature

High pressure and high temperature can stress braided hoses. Excessive temperature can cause the hose to harden and crack. The inner hose layer hardens and becomes prone to breakage. Excessive pressure can compress the internal structure, leading to leaks or bursts. Using hoses specifically designed for high-pressure, high-temperature environments, such as GONGGONG hoses, helps avoid these problems.

- High temperatures accelerate hose aging.

- High temperatures can cause the hose to harden, crack, and stiffen.

- Excessive pressure can damage the internal structure of the hose, leading to leaks.

Braided Hoses Physical Damage (Kinks, Cracks)

The most common cause of leaks in braided hoses is physical damage. Excessive bending of the hose can cause kinks, which can permanently fix the hose and obstruct water flow. Excessive bending can also cause the hose to crack, reducing its strength. Other damage includes scratches, cuts, and perforations caused by sharp objects. High temperatures and the wrong liquid can also cause hose breakage. To prevent hose damage, install the hose correctly, store it properly, and inspect it regularly.

| Measure | Description |

|---|---|

| Safe Wiring | Use clamps or straps to keep the hose away from sharp edges. |

| Sufficient Clearance | Leave space between the hose and other components to prevent squeezing. |

| Regular Inspections | Frequently inspect the hose for damage, wear, and leaks. |

| Protective Covers | Use protective covers to protect the hose from impacts and harsh weather. |

| Temperature Control | Use heat shields and insulation materials to protect the hose. |

| Proper Installation | The hose should be installed correctly by trained workers. |

Tip: Using covers and spring-loaded protective sleeves helps protect the hose from scratches and cuts. These steps will make repairing leaking braided hoses easier and reduce the number of repairs needed.

Braided hoses perform better and last longer when people follow the correct steps and choose quality products. GONGGONG hoses are robust and durable, helping to prevent leaks and other problems.

Identify Leakage in Braided Hoses

Braided Hoses Visual Signs of Leakage

Homeowners and repairmen can spot hose problems through careful observation. Regularly checking the hose helps address issues before they arise. Some signs are easy to spot and can help you determine if a problem exists.

| Indicator Type | Description |

|---|---|

| Braid Integrity Issues | If the stainless-steel braid breaks, replace the hose right away. |

| Thread Problems | Crossed threads or metal bits mean you should take out and change the hose. |

When inspecting hoses, you may also find other warning signs:

- Dampness or leaks near the hose

- Loose, torn, or worn braided layers

- Scratches, cuts, dents, or twists on the hose

- Exposed inner hose material

- Cracked or dented joints

- Rust, discoloration, or other signs of corrosion

- Damaged or loose hose sheaths or caps

- Rubbing between hoses

The following table can help you remember what to check:

| Inspection Aspect | Importance |

|---|---|

| Inspect Fittings and Connections | Stops leaks and keeps everything working well. |

| Look for Bulges or Deformations | Shows damage inside or too much pressure, so you can fix it early. |

| Check for Fluid Leaks | Small leaks can mean the hose is worn or fittings are bad. |

| Assess Hose Flexibility | If the hose bends less, it might be old or weak. |

GONGGONG hoses, made of robust stainless steel and with durable joints, help avoid many of these problems. Their unique design protects the inner braided layers and inner lining of the hose from damage.

Functional Symptoms (Reduced Flow, Water Damage)

Sometimes, leaks are difficult to detect in their early stages. People may notice changes in the water flow, which could indicate a leak in the hose.

- Slower water flow from the faucet or machine

- Water stains or pooling near the end of the hose

- Rust or discoloration on or near the hose surface

- Broken or worn stainless steel wire

- The hose appears bulging or swollen, indicating internal damage

- Rust on metal fittings concealing minor leaks

If you notice any of the above signs, repair the hose as soon as possible. Early detection of leaks aids in repair and prevents further damage. GONGGONG hoses are robust and durable, effectively addressing these issues. Their excellent design means less maintenance and smoother water flow.

Prevent Leakage in Stainless Steel Braided Hoses

Braided Hoses Proper Installation Tips

Proper installation of stainless steel braided hoses yields excellent results. Never excessively bend or twist the hose. The hose needs support to prevent sagging. The hose should only bend in one direction. Excessive bending can cause the inner wall of the hose to crack, reducing its strength. Installers should use lap flanges or fittings to prevent twisting. Use two wrenches to tighten both ends of the fitting without turning the hose. The bend should be close to the center of the fitting. Leave space between the hose and the machine to prevent tangling. These steps help prevent leaks and ensure the hose operates safely under high pressure.

Tip: Always follow the manufacturer’s instructions when installing stainless steel braided hoses. This helps avoid incorrect operation that could lead to leaks.

Braided Hoses Regular Inspection and Maintenance

Regular inspection of the hose helps prevent leaks in stainless steel braided hoses. Check the hose for cracks, bulges, or abrasions. Inspect the hose for external damage and whether it bends easily. Cleaning the hose removes dirt and chemicals that can damage it. Pressure testing shows whether the hose can withstand high pressure. If everything is in good condition, it is recommended to replace the hose every five to ten years. In harsh environments, it is recommended to replace it every three to five years. If wear or leaks are found, repair or replace the hose immediately. Taking these steps helps to fix braided hose leaks before they cause bigger problems.

Choosing Quality Braided Hoses

Choosing a premium stainless steel braided hose helps prevent leaks. It is recommended to purchase hoses made of robust stainless steel with a durable inner lining. Certifications such as SAE J517, EN 853, ISO, UL, and DOT indicate that the hose is safe and reliable. GONGGONG uses top-quality materials and inspects each hose to ensure its strength. Their hoses meet drinking water and health standards. Premium hoses have a longer lifespan and are less prone to breakage even under high pressure or harsh environments.

| Certification/Standard | Description |

|---|---|

| SAE J517 | Sets pressure ratings for hydraulic hoses |

| EN 853 | Defines performance for braided hoses |

| ISO, UL, DOT | Show safety and reliability |

Purchasing certified hoses and following proper installation and inspection procedures helps prevent leaks and ensures safety.

What to Do If Your Braided Hose Leaks

Immediate Steps to Take

If your braided hose is leaking, act quickly to prevent flooding and ensure personal safety. Here are some steps to take:

- Check the surrounding area for hazards. If water is in contact with an outlet or machine, immediately turn off the power.

- Turn off the water supply. Locate and close the shut-off valve to prevent further water leakage.

- Moisten up water on the floor. Use a towel or mop to absorb water and prevent slipping.

- Inspect the hose and the surrounding area. Check the inside of the hose and joints for damage.

Tip: Safety first. Always check for electric shock hazards before touching any wet items.

For quick repairs, you can use some tools and materials to temporarily stop the leak until a suitable repairman is found:

- Pipe clamps can be used to secure the hose tightly and temporarily stop the leak.

- Waterproof sealant can be used to seal small holes or cracks.

- Adhesive tape can temporarily cover small leaks.

- Temporary pipe repair clamps can be used to clamp the broken area.

- Sealant or caulking compound can be used to fill cracks or gaps.

- Pipe service clamps are for emergencies.

These methods can help temporarily stop a leak in a braided hose until a plumber can completely repair it.

Repair vs. Replace Decision

You need to decide whether to repair or replace the leaking braided hose. Consider the following:

- Timely hose repair prevents prolonged malfunctions and ensures equipment operates normally.

- Timely repair prevents slips and injuries, improving safety.

- Fixing leaks helps the system operate normally and maintains normal water pressure.

- Quick repair prevents dust from entering, extending the life of equipment.

- Timely repair helps prevent spills, protecting the environment.

- Repairing a hose is more economical than buying a new hose or repairing damage caused by a leak.

If the hose is very old, severely damaged internally, or lacks strength, it is best to replace it with a new one. High-quality hoses, such as those from the GONGGONG brand, are durable and perform well. When purchasing new hoses, choose products made of strong, durable materials with excellent performance.

Note: Regularly inspect hoses and promptly address problems to prevent larger malfunctions and ensure the safety of braided hoses.

Braided hoses can leak if they age or become damaged. Loose connections and corrosion can also cause leaks. People should install hoses carefully and inspect them regularly. Bend limiters and spring guards help maintain the strength of the hose. Training workers and regularly inspecting hoses ensures safety. Choosing certified, high-quality hoses like GONGGONG can reduce the risk of leaks. Taking swift action can prevent flood damage and protect your home. Most leaks can be repaired with the right steps.

FAQ

What are the main causes of leaks in braided hoses?

Loose connections, aging materials, rust, and damage can all cause leaks. Excessive bending of the hose or loose connections can also lead to leaks.

How often should braided hoses be inspected?

Experts recommend inspecting hoses every six months. Regular inspections help detect cracks, bulges, or rust early. Early detection can prevent bigger problems.

Can homeowners repair leaking braided hoses themselves?

Homeowners can use hose clamps or waterproof tape for temporary repairs. To completely solve the problem, the hose needs to be replaced. Always be careful when dealing with leaks.

What makes GONGGONG braided hoses different?

GONGGONG uses robust stainless steel and maintains strict quality control. Their hoses are less prone to rusting or tangling. Certified materials help extend the lifespan of the hoses in homes and commercial settings.